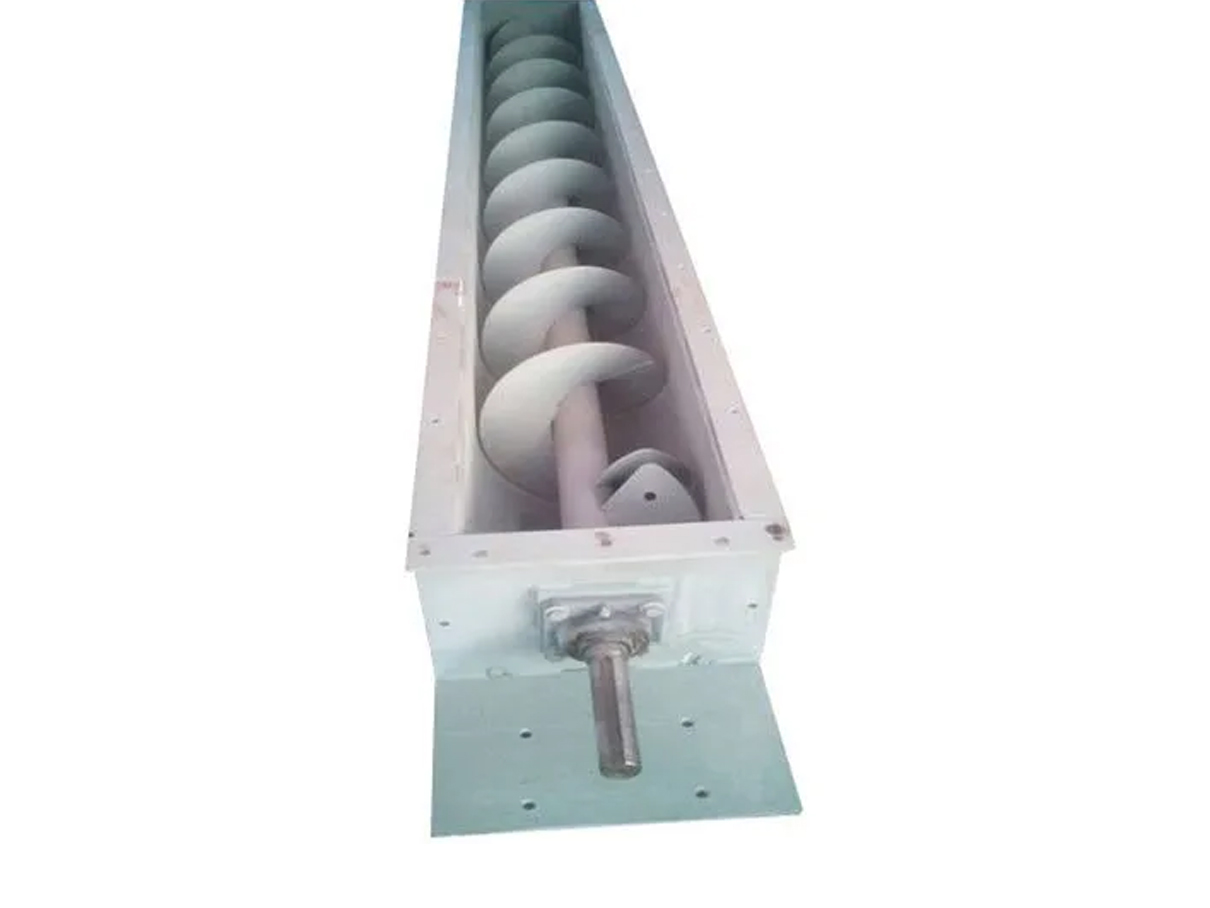

A screw conveyor is a mechanical conveying device that uses a rotating helical screw blade, typically within a tube or trough, to move bulk materials in a linear or inclined direction. Screw conveyors are widely used in various industries for transporting granular or powdered materials, such as grains, chemicals, food products, and bulk solids. They are known for their simplicity, efficiency, and versatility in material handling applications.

Key components and features of a screw conveyor include:

Screw (Auger) : The helical screw blade is the central component of the screw conveyor. It is mounted on a central shaft and is responsible for moving materials along its length. The design of the screw can vary, with different pitches, diameters, and configurations to suit specific material-handling requirements.

Tube or Trough : The screw is typically enclosed within a tube or trough that contains the material being transported. The tube or trough provides a path for the screw to rotate and move materials.

Drive Unit : The drive unit powers the screw conveyor, typically through an electric motor or a hydraulic or pneumatic system. It provides the rotational motion required for the screw to move the material.

Inlet and Outlet : Screw conveyors have an inlet for material loading and an outlet for material discharge. These points can be customized to suit the specific application.

Bearings and Seals : Bearings support the rotating shaft and help reduce friction, while seals prevent material spillage and protect the moving parts from contamination.

Hanger Bearings : In longer screw conveyors, hanger bearings may be used to support the screw and prevent sagging.

Feed and Discharge Chutes : Chutes or transition points are often used at the inlet and outlet to guide material onto or off the screw conveyor.

Screw conveyors are available in various configurations to meet specific application requirements, including:

Inclined or Vertical Conveyors : Screw conveyors can be installed at various angles to move materials both horizontally and vertically.

Flexible Screw Conveyors :These have a flexible spiral blade within a flexible tube, allowing for more flexibility in design and routing.

Shaftless Screw Conveyors : These do not have a central shaft, making them suitable for handling sticky or stringy materials and reducing the risk of material buildup.

U-Trough and Tubular Screw Conveyors : These are the two primary configurations of screw conveyors, with U-trough conveyors typically used for heavier materials and tubular conveyors for more fragile or lightweight materials.

Applications of screw conveyors include:

Material Handling : Screw conveyors are commonly used in industries like agriculture, mining, cement, food processing, and wastewater treatment for transporting bulk materials.

Mixing and Blending :Screw conveyors can be used to mix and blend materials as they are transported.

Dewatering : In wastewater treatment, screw conveyors are used to remove water from sludge and solids.

Metering and Feeding : They are used to accurately meter and feed materials into various processes.

Boiler Ash Handling : In power plants, screw conveyors are used for handling and removing ash and slag.

Screw conveyors are efficient, cost-effective, and reliable solutions for transporting bulk materials over short to moderate distances. They are chosen for their ability to handle a wide range of materials and their ease of customization for specific industrial applications.